Development of Nuri engine in the engine/propulsion test facilities

The engine/propulsion test facilities are an essential element of the independent development of liquid rocket engines. It had been difficult to develop engines in Korea due to the absence of large facilities for test high-thrust engines. Korea could conduct only design and analysis and low-thrust testing since there were no large testing facilities to test 75-ton liquid rocket engines. The performance test for the core components of the 30-ton liquid engine, which was conducted as preliminary research at the time of the Naro development, had to use overseas test facilities on rent. It was forced to pay high costs and adjust test schedules according to the overseas test institutes' schedules, which were wary of technology leak. It conducted performance tests only with miniature models.

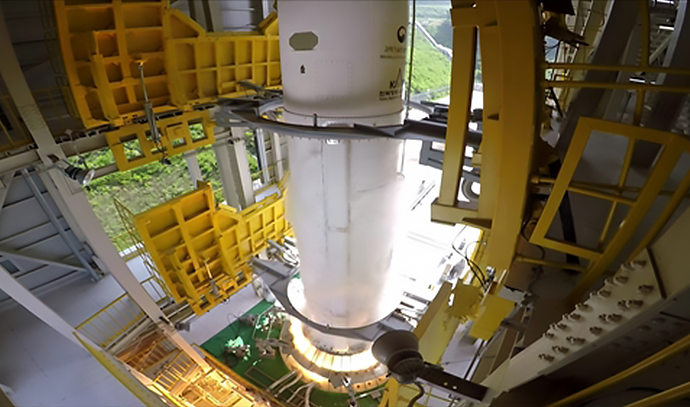

After the successful launch of the Naro, KARI built test facilities for the enigne and propulsion system of the Korea Space Launch Vehicle (Nuri) in the Naro Space Center. The engine/propulsion test facilities for Korea launch vehicles include ten types: five types of engine component test facilities, four types of engine system test facilities, and one type of comprehensive stage test facility. Six types, including the combustion chamber test facility, turbopump real-propellant test facility, third-stage engine test facility, engine ground test facility, engine high-altitude test facility, and propulsion system test facility, are installed in the Naro Space Center.

Since it is necessary to verify that the launch vehicle design and system performance are flawless, the engine/propulsion test facilities must be more accurate, and it must meet stricter specifications and performance requirements than the actual launch vehicle environment. Those test facilities for engine component, engine assembly, and propulsion system performance tests was constructed using Korean technology.

Development of future launch vehicle engines

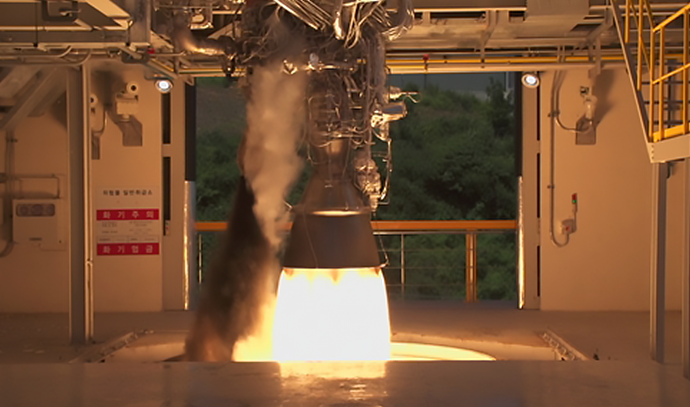

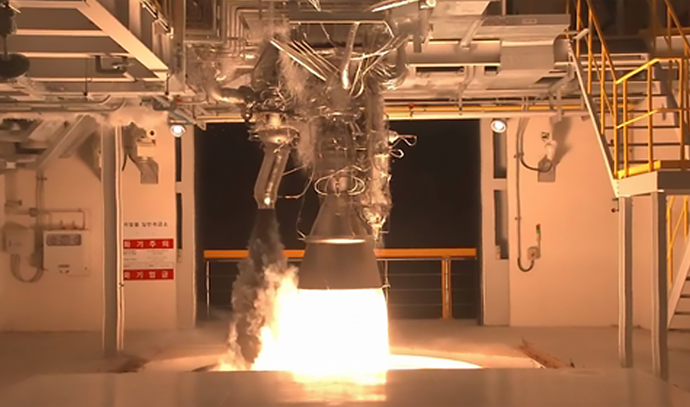

The engine/propulsion test facilities apply precision control and supply technology for cryogenic fluid (liquid nitrogen at -196 ℃ and liquid oxygen at -183 ℃) and ultra-high-pressure vapor (air, nitrogen, and helium at 400 atm). Moreover, implementing the latest control/measurement system using excellent domestic IT technology has improved the test operation safety and control/measurement accuracy compared to overseas facilities. It has applied a special civil engineering design to support high shear of 20 m or more and a structure to withstand 150-ton load and vibration.

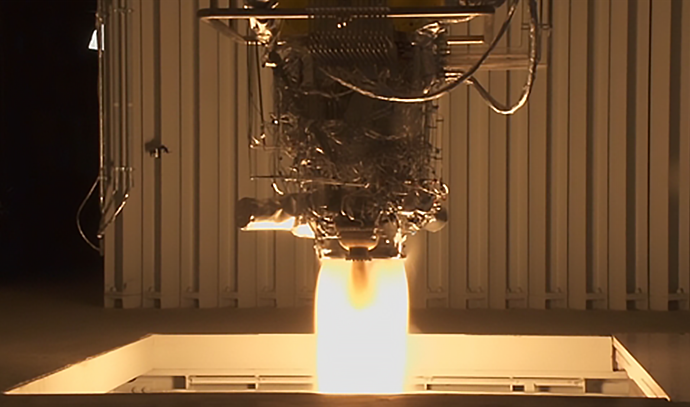

The propulsion system performance test began in earnest as the engine/propulsion test facilities have become operational. The facilities were used for tests of engine components such as turbopump and combustion chamber and engine combustion tests, including comprehensive propulsion system performance tests. They accelerated the development of the launch vehicle engines, and a unique 75-ton liquid engine was born with domestic proprietary technology through continuous engine performance tests.

After developing the Korea launch vehicle (Nuri), the engine/propulsion test facility will continue to be used for launch vehicle certification and engine performance improvement. The test facilities are also used for certification tests to check if the engine components and system meet the mass production requirements. Since they are designed to test up to twice the required thrust, they will continuously improve the 75-ton liquid engines' performance and develop new engines.

Engine/Propulsion test Facility

| Test facility name | Usage |

|---|---|

| Combustion Chamber Test Facility | Combustion Chamber/Gas Generator combustion test |

| Turbopump (real propellant) Test Facility | 7-ton/75-ton turbopump test using real propellant |

| Third-stage engine combustion test facility | 7-ton engine ground/high-altitude combustion test |

| Engine Ground Test Facility | Liquid engine ground condition combustion test |

| Engine high-altitude Test Facility | Liquid engine high-altitude condition combustion test |

| Propulsion System Test Complex | First/Second/Third-stage propulsion development/certification test |

| Turbopump (model-fluid) Testing Facility | 75-ton turbopump test using the model fluid |

| Expansion of turbopump small-size model-fluid test facility | 7-ton turbopump test using model-fluid |

| Propulsion supply system test facility | Gas/Propellant supply system development/certification test |

| Engine assembly/function test facility | Engine system assembly and function test |