Installation and Final Launch Operations

The launch pad is where the launch vehicle is installed, and the final launch operations take place. Its main roles include securing the launch vehicle, connecting electrical signal lines, and supplying propellants, such as fuel and oxidizers. Beneath the launch pad—constructed with three underground levels—are tanks that store the fuel, oxidizer, and various gases used for liquid engines. A vast network of piping and mechanical systems deliver propellants from the storage tanks to the launch vehicle. Approximately 1.5 kilometers of pressure-regulated piping extend from the tanks, spreading out in an intricate, branching layout. The total length of all electrical cabling reaches around 140 kilometers. This intricate infrastructure is why it is referred to not merely as a launch pad but as a “launch complex.” The Naro Space Center encompasses approximately 49,000 square meters of area, including underground launch pad facilities, a central utility facility, and a guidance alignment building. Launch Pad 1 (LB1), completed in 2008, spans three underground levels and one above-ground floor, covering a total area of 3,305 square meters. The Central Utility Facility houses essential systems for storing and supplying propellants, along with the core equipment for launch control. It has a footprint of 1,826 square meters and a total floor area of 2,983 square meters, with one basement level and two above-ground floors. The guidance alignment building is equipped with a theodolite, which is used to set reference points for the inertial navigation system that governs the launch vehicle’s flight trajectory.

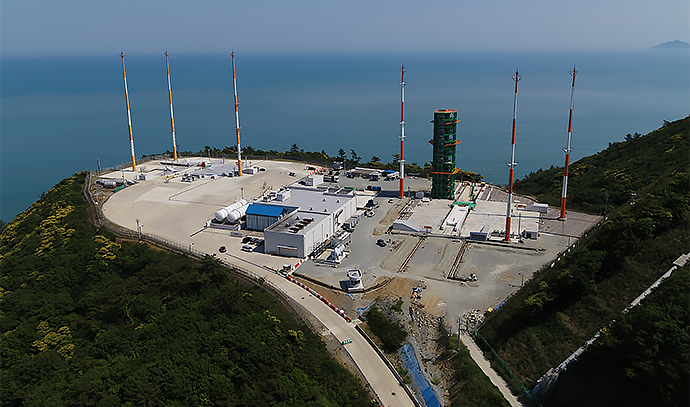

Construction of Launch Pad 2 for NURI

Launch Pad 2 was constructed using fully domestic technology to support launches of the Korean launch vehicle, NURI. This pad incorporates advanced technologies such as a Vehicle Holding Device (VHD), umbilical retraction systems, and a dedicated umbilical tower tailored to NURI's requirements.

Launch Pad 2 has three underground levels and one above-ground level, totaling 5,667 square meters. Except for a few initial design elements, all components were developed using domestic technology. As NURI is larger and heavier than the Naro-1 vehicle, and its first-stage engine produces greater thrust, Launch Pad 2 was constructed approximately 1.5 times larger to accommodate it. In order to supply propellants not only to the first stage but also to the second and third stages, each stage requires dedicated umbilical connections. Thus, a larger umbilical tower and dedicated retraction systems for each stage were installed, significantly enhancing the structure and functionality of the launch facility.

The launch pad system resembles a complex chemical plant in its design and operation. Distinctive features include specialized systems, such as the water deluge system, which cools the intense flames during engine ignition, and the Vehicle Holding Device (VHD), which holds the launch vehicle securely until liftoff. The launch complex incorporates ultra-high-pressure, cryogenic, and contamination-controlled technologies, similar to those used in semiconductor manufacturing. It employs strict environmental controls to limit moisture and particle content in the air and utilizes technologies that compress nitrogen and helium to ultra-high pressures for distribution to eight different systems. KARI, in collaboration with domestic industry partners, successfully localized the entire process—from initial design and fabrication to final assembly—for the launch pad system.