Development of Propellant Tanks Using Advanced Technology

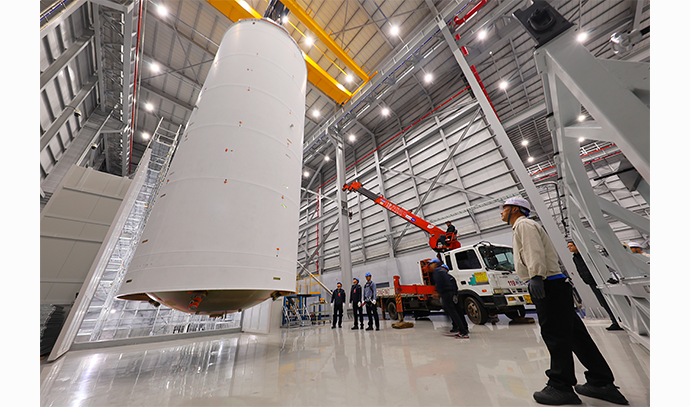

NURI is a space launch vehicle that utilizes a cryogenic oxidizer and ambient-temperature fuel as propellants. The propellant tanks account for the majority of the launch vehicle’s structure, occupying about 70–80% of its total volume.

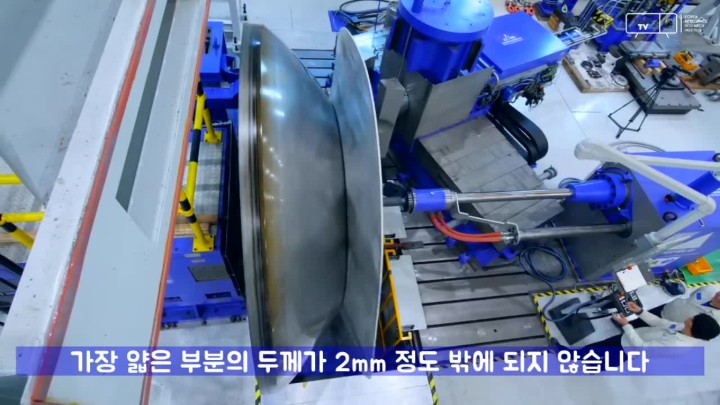

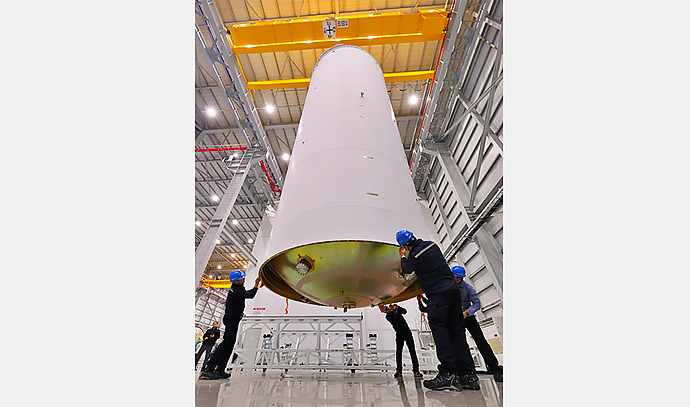

NURI’s propellant tanks can reach up to 10 meters in height and 3.5 meters in diameter, with wall thicknesses as thin as 2.5 to 3 millimeters at the thinnest point. Despite this, the tanks must withstand pressures four to six times greater than atmospheric pressure experienced at the surface, along with inertial and aerodynamic loads during flight. Given the cylindrical shape of the tanks, where the length greatly exceeds the cross-sectional diameter, they are particularly vulnerable to buckling as compressive loads are applied at both ends.

To resist these pressures and loads, the interior of the propellant tanks is reinforced with an "Isogrid Structure"—an internal lattice framework. The repeating triangular lattice configuration efficiently enhances the structural stiffness of the cylindrical body relative to its weight. Fabricating the isogrid structure demands highly complex, iterative calculations and analysis. Unlike spacefaring nations, such as the United States and Russia, Korea had to develop its first launch vehicle propellant tanks from scratch, necessitating intensive numerical simulations and iterative optimizations to determine the ideal isogrid design.

Optimized Design and Manufacturing for Liquid Dynamics

Both the kerosene fuel and liquid oxygen oxidizer are fluids, which means constant movement inside the tanks generates dynamic forces on the structure. Even in automobiles and large ships that use fuel oil, fluid sloshing can disrupt attitude control, requiring the installation of stabilizing devices. The same applies to NURI’s propellant tanks but on a much larger scale. Excessive fluid movement inside these tanks could severely impact the launch vehicle’s stability. Therefore, optimized designs and manufacturing techniques were essential for managing the tank size and the dynamics of the fuel and oxidizer.

Additionally, NURI uses liquid oxygen as an oxidizer, which is extremely cryogenic at -183°C and prone to rapid vaporization. Thus, the tank plays a critical roleduring the oxidizer's injection and storage phases.