Electro-optical payload

(AEISS, Advanced Earth Imaging Sensor System)

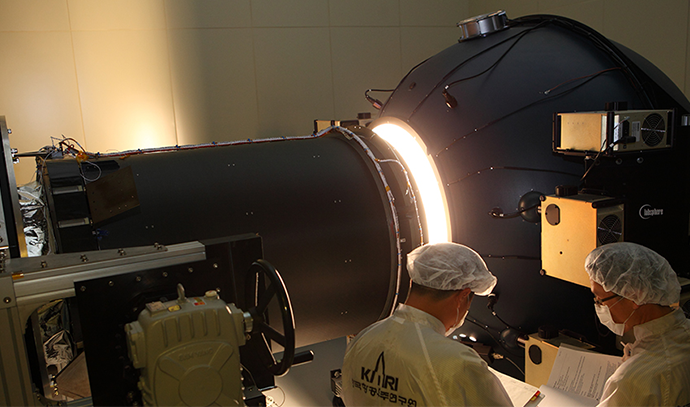

An electro-optical payload is a camera that records the visible light band that the human eyes can see. Electro-optical cameras include optical mirrors that reflect light coming from the ground, high-stability telescope structure(HSTS) that supports the reflector and payload components, focal plane unit(FPU) that converts the light from the reflector into electronic signals, and camera electronics unit(CEU).

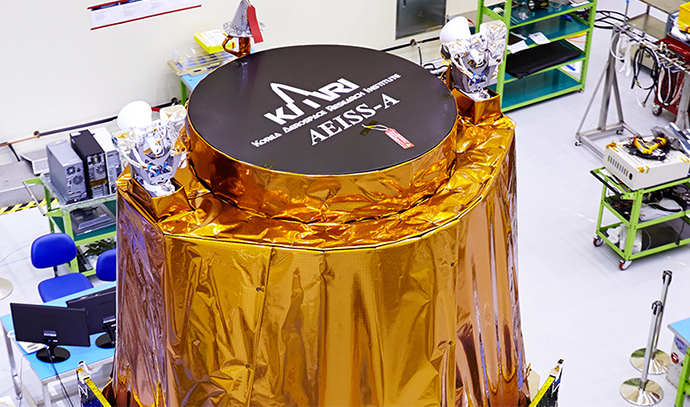

KARI independently developed a world-class electro-optical payload, AEISS(Advanced Earth Imaging Sensor System), based on the technology acquired through the development of Arirang 1 and Arirang 2. Except for some parts, AEISS was developed with Korean technology from design to precise assembly, alignment, testing, and final verification in the simulated space environment.

Ultra-precision technology available in very few countries

As a key component of an electro-optical payload, the reflector acts like a camera lens. The process of manufacturing the reflector surface requires precision at the level of cutting hair into thickness of 1/50,000. Moreover, the surface should be in an aspherical shape to prevent distortion of the image. It has to be made to bend the surface unevenly, requiring high level of skill. The Hubble Telescope's failure (550 nm) was also an error that occurred during processing measurements. Assembling and aligning the optical system require ultra-precision higher than 1/5,000 of the thickness of hair. It also needs high-level technology to block even the minute vibrations generated by cars' movement around people or buildings.

Moreover, the satellite has to withstand the load of several times the gravitational acceleration during the process of launch into space on a space launch vehicle and the temperature difference of more than 100oC in a vacuum environment while carrying out its mission for several years. That is why few countries such as the US and France have cutting-edge satellite electro-optical camera technology. High-performance electro-optical cameras cannot be developed through technology transfer or joint development. Therefore, it is important to secure high-performance electro-optical camera development technology independently.

Arirang 3 and Arirang 3A were equipped with AEISS(Advanced Earth Imaging Sensor System) and AEISS-A(Advanced Earth Imaging Sensor System-A), respectively. AEISS mounted in Arirang 3 is a 70cm-resolution electro-optical camera unit. AEISS can precisely identify vehicles moving on the ground while flying at 7km/s at an altitude of 700km.

KARI developed AEISS-A mounted in Arirang 3A as a succeeding model of AEISS. The optical resolution of AEISS-A is 55cm, and the camera is equipped with an IR channel to enable nighttime photography and heat detection with an IR sensor.

Arirang 7, which is currently under development, will be equipped with AEISS-HR (Advanced Earth Imaging Sensor System-High Resolution). AEISS-HR boasts of the world's highest optical performance level of 30cm. Arirang Satellite 7 is designed to acquire 30cm ultra-high-resolution images with optical unit measuring 1.5 times of 0.7m. KARI is independently developing the satellite using the core technologies it has acquired by developing existing optical satellites. They include satellite maneuvering and altitude stabilization, camera gravity-compensated optical system alignment, lightweight composite optical structure with high stability, optical transmission for real-time processing and storage of large-capacity image data, and storage of data-sized terra-bit or more. Moreover, real-time compression and encryption in high-speed parallel processing were developed to transmit stored images to the ground within a limited time. Arirang 7 is expected to show 3.4 times' vehicle type identification(including small cars and trucks) capability and improved maneuverability compared to Arirang 3A.

KARI plans to launch Arirang 7 equipped with a 30cm-class ultra-high-resolution camera next year. The subsequent satellite, Arirang 7A, will be equipped with a 25cm-class ultra-high-resolution camera. Few countries like the United States, Europe, and Japan currently have satellites equipped with a 30cm-class ultra-high-resolution camera.

KARI has used imported reflectors for up to Arirang 3, but the Space Core Technology Development Project successfully manufactured reflectors that could be used for satellites. As a result, the 50cm-class optical camera for Compact advanced satellite 500-1(CAS 500-1) will be equipped with Korea’s independently developed reflector. Except for photodetectors(CCD), the Compact advanced satellite 500-1(CAS 500-1) succeeded in localizing payload components, which had been completely dependent on overseas technology and achieved a localization rate of 98.6%. Moreover, Arirang 7’s 30cm-class optical system will also use some of the reflectors developed in Korea.