Distribution Limitation (무단복사 배포금지), KARI Proprietary Data : The data contained in this document, without the

permission of KARI, shall not be used or disclosed for any purpose other than GK2 Development. This restriction does not

limit the right to use or disclose this data if legally obtained from another source without restriction. The data subject to this

restriction is contained on all pages.

Korea Aerospace Research Institute

GEO-KOMPSAT Program Office

45 Eoeun-dong Yuseong-gu Daejeon 305-333

Republic of Korea

Request for Proposal

of GEO-KOMPSAT-2 EEE Part Procurement

HEATER (FLEXIBLE)

Date: 19 April 2016

Doc. No: GK2-HTR-01

Issue: F.00

Total page: 9

Table of Contents

1. INTRODUCTION ......................................................................................................................................... 1

1.1 GENERAL .................................................................................................................................................. 1

1.2 PART IDENTIFICATION NUMBER (PIN) ....................................................................................................... 1

2. APPLICABLE DOCUMENTS ..................................................................................................................... 1

3. STATEMENT OF WORK ............................................................................................................................ 2

3.1 GENERAL .................................................................................................................................................. 2

3.2 ITEM REQUIREMENTS ................................................................................................................................ 2

3.3 ELECTRICAL CHARACTERISTICS AND PHYSICAL DESIGN ........................................................................... 2

3.3.1 Electrical Characteristics ............................................................................................................... 2

3.3.2 Maximum Ratings .......................................................................................................................... 2

3.3.3 Material and Finishes ..................................................................................................................... 3

3.3.4 Weight ............................................................................................................................................. 3

3.3.5 Physical Dimensions and Heater Outline ..................................................................................... 3

3.3.6 Marking ........................................................................................................................................... 3

3.4 PRODUCTION CONTROL ............................................................................................................................ 4

3.4.1 Robustness of Terminations .......................................................................................................... 4

3.5 SCREENING TESTS.................................................................................................................................... 4

4. QUALITY ASSURANCE ............................................................................................................................. 5

4.1 DELIVERABLE DATA .................................................................................................................................. 5

4.2 RECEVING INSPECTION ............................................................................................................................. 5

5. PREPARATION FOR DELIVERY .............................................................................................................. 5

5.1 PACKING ................................................................................................................................................... 5

5.2 MARKING FOR SHIPMENT .......................................................................................................................... 5

APPENDIX. HEATER CHARACTERISTICS ................................................................................................ 6

RFP for EEE Part Procurement

for

GK2 HEATER

1.

INTRODUCTION

1.1 GENERAL

This document defines the basic electrical and environmental requirements for the flexible single

layer electrical heaters. The intended use of these heaters is to provide a stabilized temperature over

the operating temperature range of –65 C to +200 C. The operating life shall be a minimum of 12

years after a storage time of 7 years over the temperature of –65 C to + 200 C.

1.2 PART IDENTIFICATION NUMBER (PIN)

The PIN is formed as follows. The last three digits (indicated by –xxx) will be serial number of the part.

Manufacturer specific identification can be added if applicable.

GK2 – HTR – 01 - FM - XXX

Serial number

ESCC Component Number

: ESCC Component Numbers are In accordance to ESCC4009/002 or ESCC4009/003.

2. APPLICABLE DOCUMENTS

The following documents form part of this specification and shall be read in conjunction with it. In the

event of conflict, this document shall take precedence.

(a) ESCC Generic Specification No. 4009 : Resistors, Heaters, Flexible

(b) ESCC Detail Specification No. 4009/002 : Resistors, Heaters, Flexible, Single and Double Layer

(c) ESCC Detail Specification No. 4009/003 : Resistors, Heaters, Flexible, Single and Double Layer

Based on Type FHK

(d) ESCC Generic Specification No. 3901: Wires and Cables, Electrical, 600V, Low Frequency

(e) ESCC Generic Specification No. 3901/019: Polyimide Insulated Wires and Cables, Low

Frequency, 600V, -200 to +200C

(f) ESCC No. 21700 : General Requirements for the Marking of ESCC Components.

(g) ESCC No. 20600 : Preservation, Packaging and Dispatch of ESCC Electronic Components.

(h) MIL-P-46112 : Military Specification for Polyimide Plastic Sheet and Strip

(i) ASTM-D5213: Standard Specification for Polyimide Resin Film for Electrical Insulation and

Dielectric Applications.

(j) ESCC Basic Specification No. 2054009 : External Visual Inspection of Flexible Heaters

3. STATEMENT OF WORK

3.1 GENERAL

The bidder shall be the vendor or manufacturer registered in ESCC Qualified Part List (QPL).

3.2 ITEM REQUIREMENTS

The individual item requirements shall be in accordance with 1) ESCC 4009 and 4009/002 or 2)

4009/003 (variant 02) including production controls, screening tests, test methods and procedures,

deliveries, packing and dispatch and specified herein. This heater shall be capable of meeting all

design, materials, electrical, environmental, and mechanical requirements of 1) ESCC 4009 and

4009/002 or 2) 4009/003 (variant 02), unless otherwise stated.

3.3 ELECTRICAL CHARACTERISTICS AND PHYSICAL DESIGN

3.3.1 ELECTRICAL CHARACTERISTICS

3.3.1.1 Operating Temperature

Operating temperature shall be -65C to +200C.

3.3.1.2 Operating Voltage

Operating voltage range of heater shall be 48.8V to 50.5V each.

3.3.1.3 Resistance

Resistance of each heater circuit shall be within ±5%.

3.3.2 MAXIMUM RATINGS

The maximum ratings shall not be exceeded at any time during use or storage. Maximum ratings

shall only be exceed during testing to the extent specified in this specification and when stipulated in

Test Methods and Procedures of the ESCC Generic Specification.

Characteristics

Symbols

Maximum Ratings

Units

Remarks

Operating

Temperature Range

TOP

-65 to +200

C

Storage Temperature

Range

TSTG

-65 to +200

C

Power Density when

suspended in Still Air

at 25C

P

0.54

W/cm2

Note 1

NOTES: 1. Based on heated area (i.e. edges and termination area excluded).

3.3.3 MATERIAL AND FINISHES

3.3.3.1 Heater Resistive Element

The heater resistive element shall be made of flexible nickel/chromium/iron alloy.

3.3.3.2 Protective Coating

Heater resistive elements and terminal lead connections shall be completely coated with Polyimide

Polymer/FEP in accordance with MIL-P-46112 (as superseded by ASTM-D5213).

3.3.3.3 Terminal Leads

Terminal leads shall be made of multi-strand silver-plated copper in accordance with ESCC Generic

Specification No. 3901. Wires used for terminal leads shall be ESCC qualified 3901 series. Appendix

table shall be followed for detail wire type, gauge and specification. Terminal leads shall be

electrically welded to the heater resistive element.

3.3.4 WEIGHT

The maximum weight for these heaters shall be TBD.

3.3.5 PHYSICAL DIMENSIONS AND HEATER OUTLINE

The physical dimensions and electrical characteristics are attached in the attachment 1.

3.3.5.1 Lead Wire Length and Gauge

The lead wire length shall be 915 mm and wire gauge shall be 24AWG or 26AWG depending on

electrical load. (see Appendix)

3.3.5.2 Dimension Tolerance (In accordance to ESCC4009/002 or ESCC4009/003)

Space between leads, Heating Area : ±0.5mm.

Lead length : ±10%.

3.3.6 MARKING

The marking shall be in accordance with the requirements of ESCC Basic Specification No. 21700

and as follows.

The information to be marked on the component shall be (but not be limited to) :

a. KARI Part Number

b. ESCC Component Number and ESCC qualified component symbol

c. Serial Number

d. Manufacturer’s Name

e. Date code

3.4 PRODUCTION CONTROL

Production control shall be in accordance with ESCC 4009, para. 5.

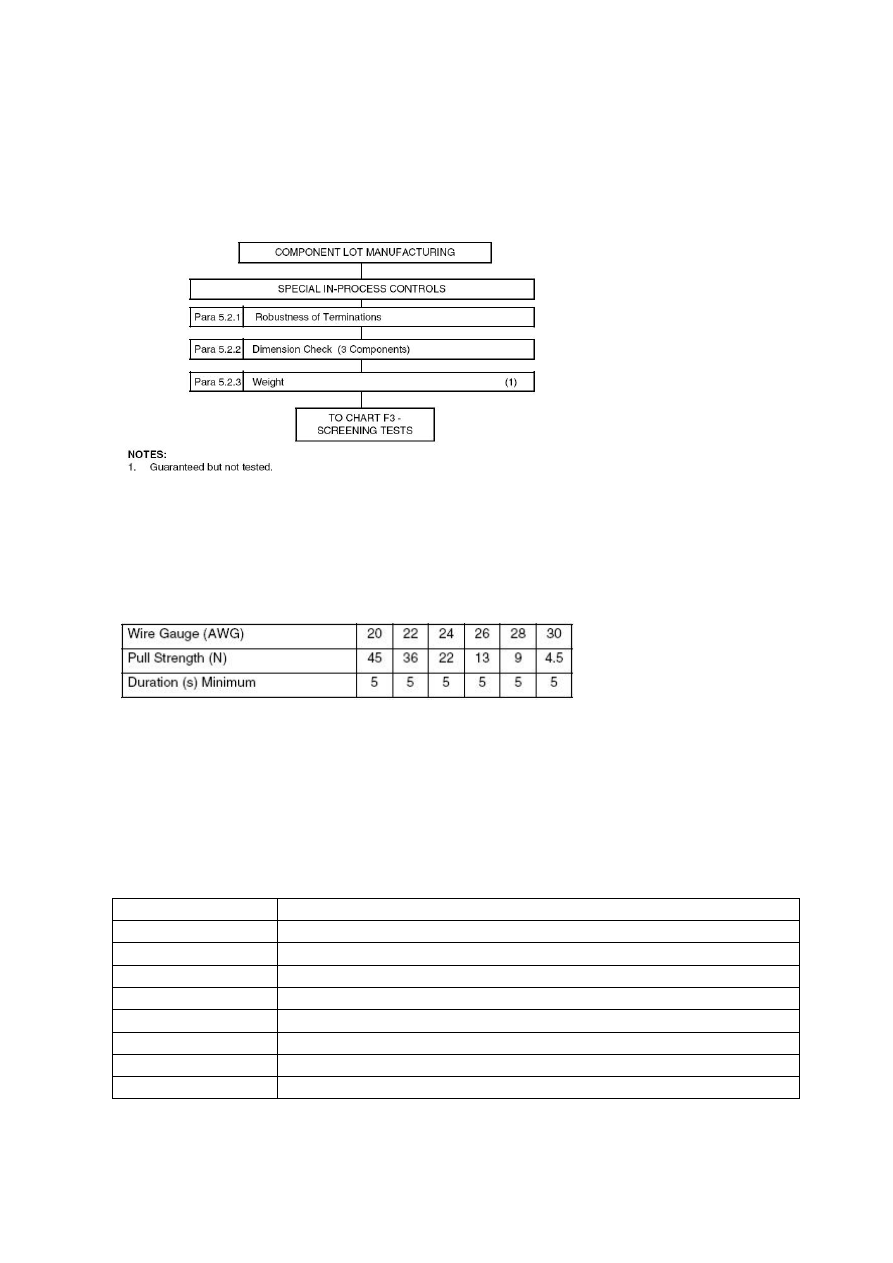

Chart F2 – Production Control in ESCC 4009.

3.4.1 ROBUSTNESS OF TERMINATIONS

The test conditions for robustness of terminations, tested as specified in the ESCC Generic

Specification, shall be as follows and apply to a single terminal lead at a time.

3.5 SCREENING TESTS

Heaters procured to this document shall be subjected to the following screening test in accordance

with ESCC Generic Specification No. 4009 with failure criteria in it. All electrical measurement

method, condition, and criteria shall also be followed by relative paragraph in detail specification,

ESCC No. 4009/002 or ESCC No. 4009/003.

ESCC 4009 ISSUE3

COMPONENTS FROM PRODUCTION CONTROL

Para. 8.1.3

Room Temperature Electrical Measurements

Para. 8.2

Rapid Change of Temperature

Para. 8.3

Overload (4 Components)

Para. 8.4

Burn-in

Para. 8.1.2

High and Low Temperatures Electrical Measurements (4 Components)

Para. 8.1.3

Room Temperature Electrical Measurements

Para. 6.4

Check for Lot Failure

Para. 8.5

External Visual Inspection

Deviations from the above Screening test in Generic Specification shall be applied in accordance

with detail specification, ESCC No. 4009/002 or ESCC No. 4009/003.

4. QUALITY ASSURANCE

4.1 DELIVERABLE DATA

The following data shall be delivered with the Heaters shipment. The data shall include, but not be

limited to, the followings:

KARI purchase order number

KARI Part number and serial number

ESCC Part number

Lot identification

Quantity shipped

Weight

Certificate of Conformance

Test Reports (in-production and screening test)

4.2 RECEVING INSPECTION

Upon receipt at KARI, receiving inspection shall perform sample Visual and mechanical inspection to

verify materials, physical dimensions, making and workmanship.

5. PREPARATION FOR DELIVERY

5.1 PACKING

The packaging and dispatch of components to this specification shall be in accordance with the

requirements of ESCC Basic Specification No. 20600.

5.2 MARKING FOR SHIPMENT

Shipping container shall be labeled to show at least the following:

a) Item Name

b) Name of Manufacturer

c) KARI Part Number and Serial Number

d) Contract or Purchase Order Number

e) Supplier’s Code Number and Revision Information

f) Notice of Handling Caution

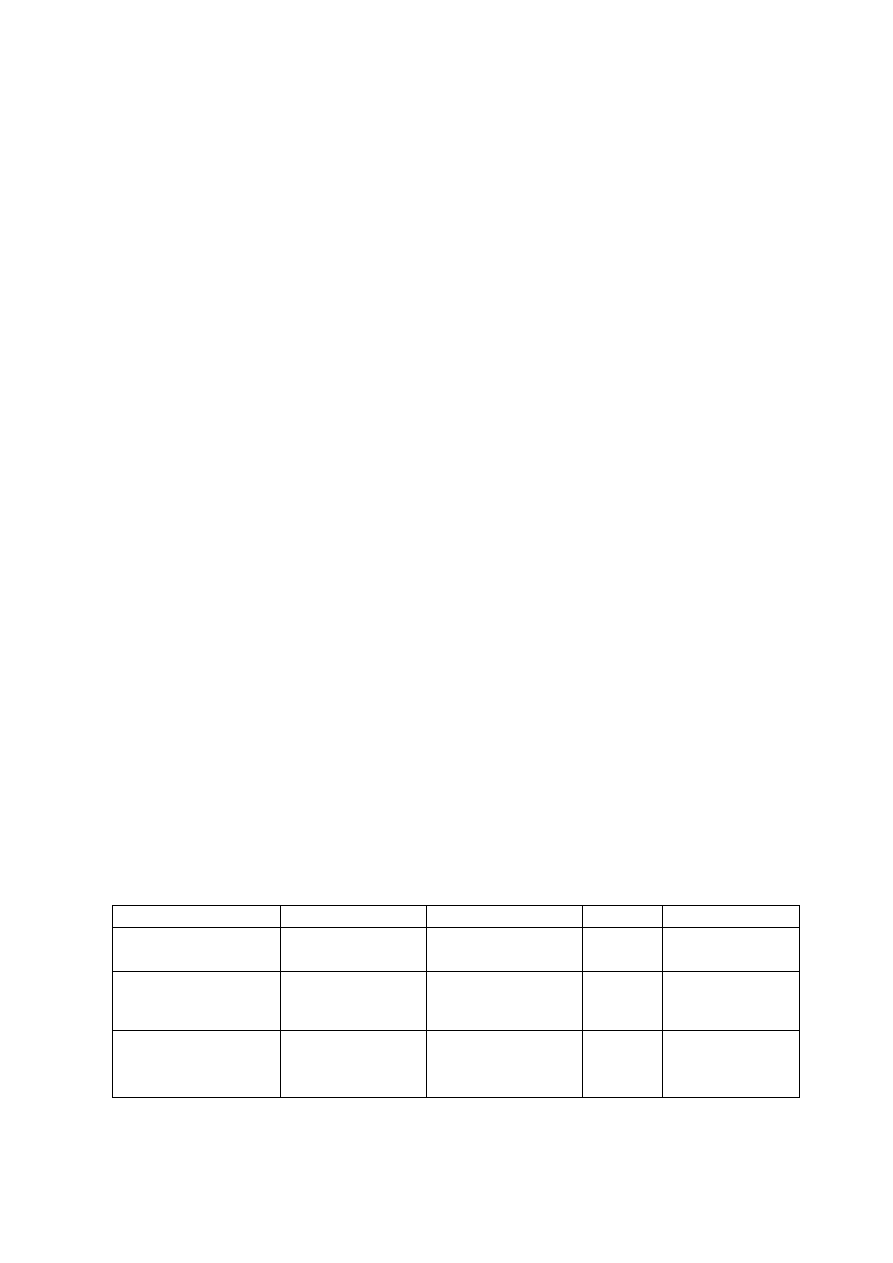

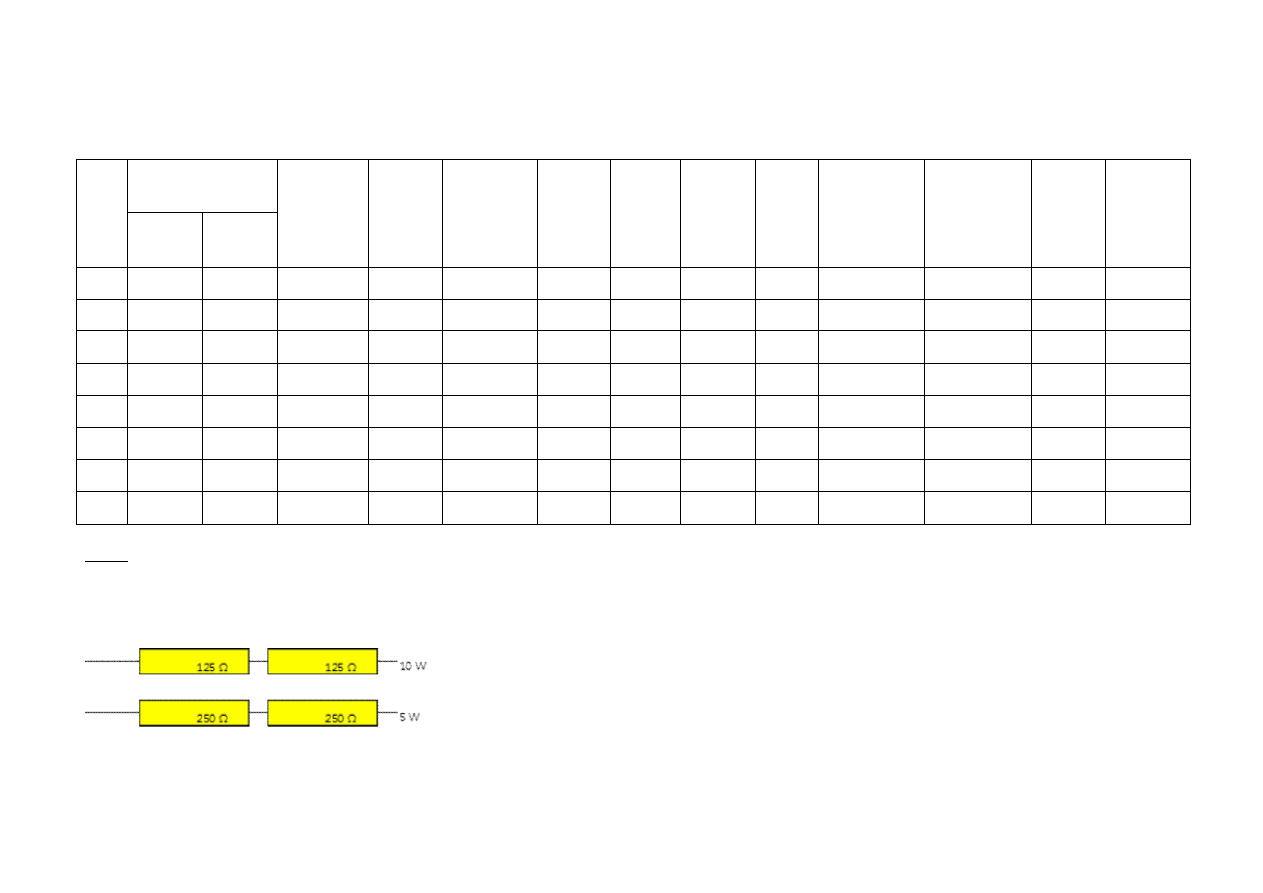

APPENDIX. HEATER CHARACTERISTICS

Item

Overall Dimension

of the Polyimide

polymer/FEP

Resistance

(Ω )

No. of

Layers

Power (W)

to each

heater at

50 V

Current

(A)

AWG

Gauge

(AWG)

Al Foil

Backing

Wire

length

(mm)

Wire Type

(ESCC3901/

019-03)

(Note2)

Heater

Configuration

Quantity

(EA)

Comment

Length

(mm)

Width

(mm)

1

150

26

83.3

1

30

0.6

26

Yes

915

Straight

Parallel

10

2

125

26

100

1

25

0.5

26

Yes

915

Straight

Parallel

35

3

100

26

125

1

20

0.4

26

Yes

915

Straight

Parallel

50

4

95

20

167

1

15

0.3

26

Yes

915

Straight

Parallel

40

5

135

12

250

1

10

0.2

26

Yes

915

Straight

Parallel

120

6

65

20

125

1

20

0.4

26

Yes

915

Straight

Serial

75

Note3

7

38

12

250

1

10

0.2

26

No

915

Straight

Serial

130

Note3, 4

8

65

20

250

1

10

0.2

26

Yes

915

Straight

Parallel

65

Notes:

1. In terms of heating area, the watt density shall be less than 1.0W/cm2 for all items above.

2. Wire type: ESCC3901/019-03, Straight

3. The heaters shall be used in series:

4. The heaters might be mounted on a curved surface.